At Helispecs we offer a wide range of Helicopter Repair & Maintenance Services and Upgrades

We work with not only Robinson but any Small to Medium Size helicopters.

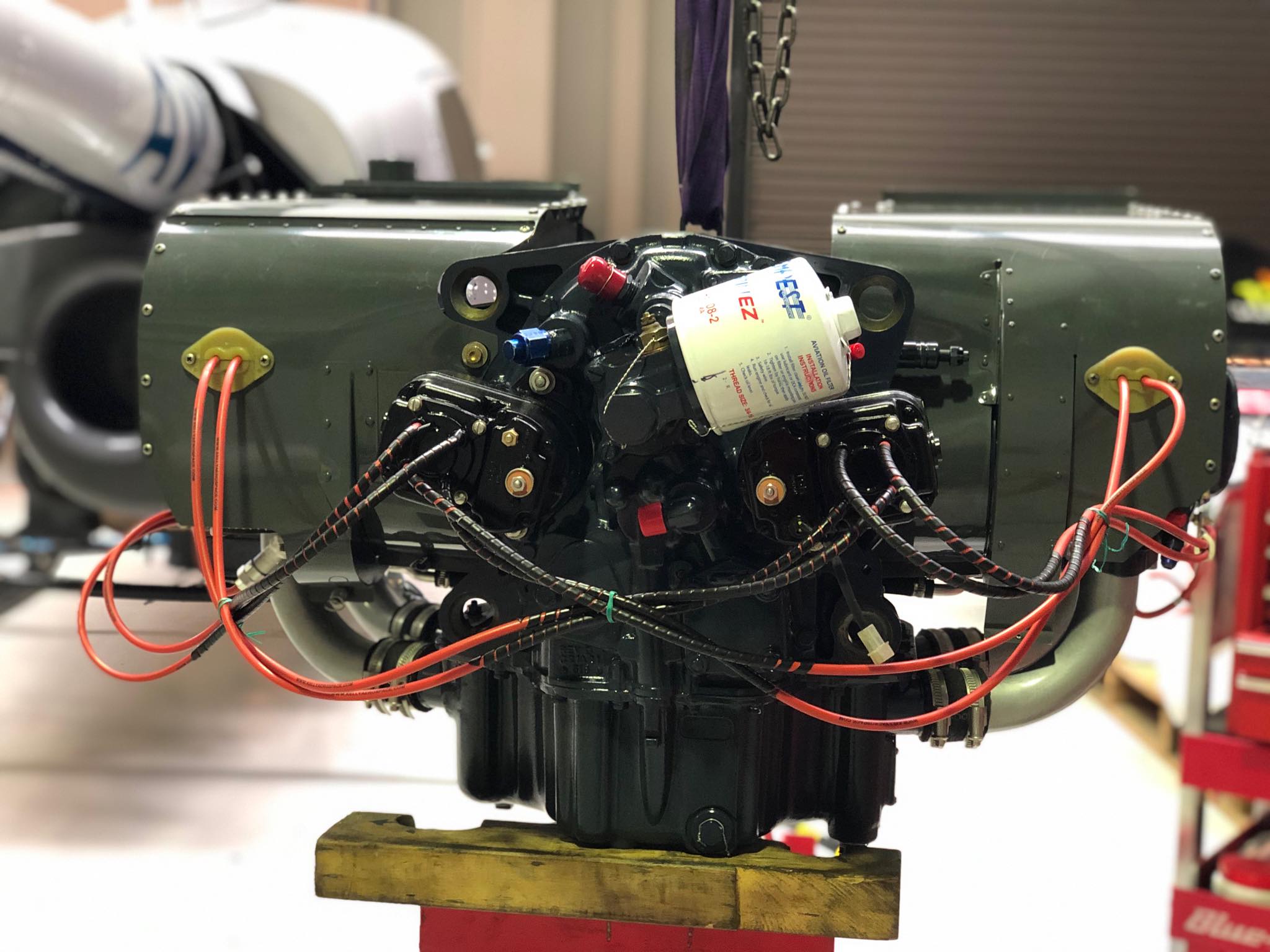

Robinson R22 Alpha & Beta Maintenance

R22 100 Hour / Annual Inspection

Every 100 hours:

- Inspect per Section 2.400.

- Inspect and service engine per Lycoming Operator’s Manual, SI 1129, SI 1191, SI 1080, SB366, SB480

- Inspect and service TCM ignition components per TCM SB643

Every 12 Months:

- Inspect per Section 2.400.

- Check and inspect chip detectors

- Inspect and service engine per Lycoming Operator’s Manual

- Inspect and service TCM ignition components per TCM SB’s

R22 12 Year Inspection

If less than 2200 hours time-in-service, but 12 years or more have elapsed since helicopter was new or last overhauled we can perform a 12 year inspection in accordance with the Robinson manual using new or overhauled parts.

This inspection does not supersede 2200 hour inspection and overhaul requirements.

R22 2200 Hour Inspection

We can restore your ship to like-new condition.

Having your 2200 hour inspection done by us will save you time and money. We are Authorized Overhaul Facility. Therefore, you have the choice of replacing your components or overhauling them as needed.

We also offer custom options like avionics upgrades and field upgrades

R22 Scheduled Maintenance

First 25 hours:

- Change oil and filter and inspect oil suction screen and filter per Lycoming SB480.

- Check alternator belt tension per Lycoming system.

- Verify sheave alignment.

- Service Instruction SL 1129.

- Verify track and balance of drive

Every 50 hours:

- Change oil and filter and inspect oil suction screen and filter per Lycoming SB480E.

- Inspect and service engine per Lycoming Operator’s Manual and SI 1080.

First 100 hours:

- Drain and flush gearboxes per Sections 1.120 1.130.

- Check engine exhaust valve guide clearance per Lycoming SB388C.

Every 100 hours:

- Inspect per Section 2.400.

- Inspect and service engine per Lycoming Operator’s Manual

- Inspect and service TCM ignition components per TCM SB643

Every 300 hours:

- Lubricate A181-4 Rev K, Rev L, and Rev M bearings per Section 2.502.

- Lubricate A184 bearing per Section 2.503.

- Inspect valves and check engine exhaust valve guide clearance per Lycoming SB301, SB388, and Operator’s Manual.

Every 500 hours:

- Drain and flush gearboxes per Sections 1.120 1.130.

- Inspect spindles per FAA AD 88-26-01 R2.

Every 800 hours:

- Lubricate A181-4 Rev N bearing per Section 2.502.

Every 2200 hours:

- Overhaul helicopter per Section 2.700.

- See R22 2200 Hour Inspection

Calendar

Every 4 months:

- Change oil and filter and inspect oil suction screen and filter per Lycoming SB480E.

Every 12 months:

- Inspect per Section 2.400. Lubricate A181-4 Rev K, Rev L, and Rev M bearings per Section 2.502.

- Lubricate A184 bearing per Section 2.503.

- Inspect emergency locator transmitter (ELT) per FAR 91.207.

- Clean gearbox chip detectors per Section 1.115.

Every 24 months:

- Test and inspect transponder per FAR 91.413.

- Every 4 years: Lubricate A181-4 Rev N bearing per Section 2.502.

- Overhaul TCM magnetos per TCM SB643B.

Every 12 years:

- Perform 12-year inspection and limited overhaul per Section 2.600, or overhaul per Section 2.700.

- See R22 12 Year Inspection

R22 Special Inspection

R22 Special Upgrades

We have a big experience in Design and Approval with Custom Equipment for the Robinson Helicopters.

Robinson R44 Astro & Raven Maintenance

R44 100 Hour / Annual Inspection

Every 100 hours:

- Inspect per Section 2.400. Inspect and service engine per Lycoming Operator’s Manual, SI 1129, SI1191, SI1080, SB366 (Carburetor), SB 342 (IO-540)

- As required, inspect and service TCM ignition components per TCM SB643B.

- Inspect emergency locator transmitter (ELT) per 14 CFR Part 91.207.

Every 12 Months:

- Inspect per Section 2.400. Clean gearbox chip detectors per Section 1.1 15.

- Inspect emergency locator transmitter (ELT) per 14 CFR Part 91.207

- Inspect optional pop-out floats per Section 5.630

R44 12 Year Inspection

Every 12 years perform 12-year inspection and limited overhaul per Section 2.600 or overhaul per Section 2.700.

If there is less than 2200 hours time-in-service, but 12 years or more have elapsed since the helicopter was new or last overhauled we can perform a 12 year inspection in accordance with the Robinson manual using new or overhauled parts.

This inspection does not supersede 2200 hour inspection and overhaul requirements.

R44 2200 Hour Inspection

We can restore your ship to like-new condition.

Having your 2200 hour inspection done by us will save you time and money. We are Authorized Overhaul Facility. Therefore, you have the choice of replacing your components or overhauling them as needed.

We also offer custom options like avionics upgrades and field upgrades

R44 Scheduled Maintenance

First 25 hours:

- Change oil and filter and inspect oil suction screen and filter per Lycoming SB480E.

- Check alternator belt tension per Lycoming Service Instruction SI 1129.

Every 50 hours:

- Inspect and service engine per Lycoming Operator’s Manual, SL 1080,

- Change oil, oil filter, and inspect oil suction screen and removed filter per Lycoming SB480E.

First 100 hours

- Drain and flush gearboxes per Sections 1.120 1.130.

- Inspection: Check engine exhaust valve guide clearance per Lycoming SB388C.

Every 100 hours:

- Inspect per Section 2.400. Inspect and service engine per Lycoming Operator’s Manual, SB366, S11G8GB, SI1 1298, and SB342E (I0-540 only).

- As required, inspect and service TCM ignition components per TCM SB643B.

Every 300 hours:

- Lubricate C181-3 bearing per Section 1.140.

- Replace hydraulic filter per Section 1.170.

- Inspect valves and check engine exhaust valve guide clearance per Lycoming SB301B, S8388C, and Operator’s Manual.

Every 500 hours:

- Drain and flush gearboxes per Sections 1.120 1.130.

- Clean gearbox chip detectors per Section 1.115. Verify magneto drive cushion pliability.

- Service collective spring assembly (manual controls only) per Section 8.221.

- As required, inspect and service TCM ignition components per TCM SB658 and SB663A.

Every 2200 hours:

- Overhaul helicopter per Section 2.700.

- See R44 2200 Hour Inspection

Calendar

Every 4 months:

- Change oil, oil filter, and inspect oil suction screen and removed filter per Lycoming SB480E.

Every 12 months:

- Inspect per Section 2.400.

- Clean gearbox chip detectors per Section 1.1 15.

- Inspect emergency locator transmitter (ELT) per 14 CFR Part 91.207.

- Inspect optional pop-out floats per Section 5.630.

Every 24 months:

- Test and inspect transponder per 14 CFR Part 91.413.

Every 3 years:

- Lubricate C181-3 bearing per Section ’1.140.

- Inspect optional popout floats per Section 5.640.

- Hydrostatic test pressure cylinder.

- Every 4 years

- Overhaul TCM magnetos per TCM 886438. Verify magneto drive cushion pliability.

Every 12 years

- Perform 12-year inspection and limited overhaul per Section 2.600, or overhaul per Section 2.700.

- See 12 Year Inspection

R44 Special Inspection

R44 Special Upgrades

We have a big experience in Design and Approval with Custom Equipment for the Robinson Helicopters.

Modifications and Conversions

At Helispecs we have a big experience in modifications of Robinson and Other Helicopters. Get in touch to discuss your requirements. We would be happy to work on your project.

We can travel to your hangar or to an aircraft in the field to perform the required upgrade or helicopter repair. We work around the Central Plateau, but happy to come anywhere on the North Island.

Component Overhaul

We are working with Robinson and ANY other small to medium size helicopters

R22 Alpha & Beta Component Overhaul

- Main Rotor Blade and Spindle Repair

- Main Rotor Gearbox 12 year inspection and Upper beairng replacement

- Swashplate Overhaul / Repair

- Clutch Assembly overhaul and Repair A018-1 & -2

- Tail Rotor Gearbox input seal replacement

- Tail Rotor blade replacement / Hub inspection

- Landing gear NDT and fitting inspection

- Rotor Head 2200 hour overhaul

- Steel frame NDT inspection

R44 Astro & Raven Component Overhaul

- Main Rotor Blade and Spindle Repair

- Swashplate Overhaul / Repair

- Clutch Assembly overhaul and Repair C018-2 & -3

- Fanshaft Overhaul / Repair

- Main Rotor Gear Box 12 year inspection and upper bearing replacement

- Hydraulic Servo Seal Repair

- Tail Rotor Blade replacement

- Main Rotor head 12 year inspection

Parts Supply

Please Contact Us for the parts you need:

Custom Equipment

At Helispecs we have a big experience in installing the role and custom equipment on helicopters. Spray systems, hooks, electronics and everything else. With 40+ years of experience, we are focused on safety and results. Get in touch to discuss your requirements.

Logistics

With a well-established international logistics network, Helispecs offers logistics services of both components and entire helicopters. Get in touch to discuss your case.